Bearing Currents, also known as common mode currents, are damaging to equipment and result in motor down-time. Voltage in the shaft is induced by the magnetic fields that are created by current flowing through the motor winding. If a motor is connect to the utility, these magnetic fields are typically balanced and the net voltage will sum to zero. However, when motors are asymmetrical within the winding a net voltage different than zero can occur (especially with the use of VFDs) which can lead to bearing currents. Common mode voltage occurs when the voltages on the three output lines of a drive do not sum “instantaneously” to zero.

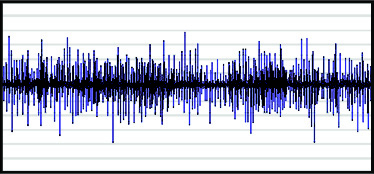

Another cause of an imbalance in the supply voltage is the use of Pulse Width Modulation (PWM) motor control. Because the motor is being supplied by pulses, it becomes instantaneously unbalanced, causing a neutral point that is not equal to zero. The new neutral voltage is proportional to the common-mode voltage, or DC link voltage, of the drive. This new neutral can yield high-frequency currents in the bearing that are limited in amplitude and duration.

Motor Protection Solutions

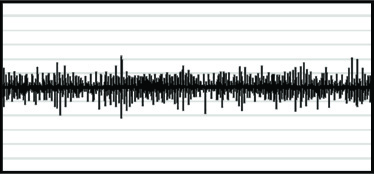

Filtering can be applied to the motor side of the drive to remove these high frequency currents. The V1K dV/dt filter substantially slows down the rate of change of PWM switching as seen by the load. This reduction in the rate of change results in increased capacitive coupling impedance between bearings and bearing races. This increase in impedance, in turn, reduces the damaging Common Mode currents and increases motor up-time.