Drive-Applied Passive Harmonic Filter

The HG7 Harmonic Filter, when applied at the variable frequency drive, provides a low impedance path for the major harmonic currents demanded by the drive.

The HG7 Harmonic Filter, when applied at the variable frequency drive, provides a low impedance path for the major harmonic currents demanded by the drive.

This greatly reduces the amount of harmonic current flowing through the distribution system and results in improved power factor, lower RMS currents, lower harmonic current distortion, lower harmonic voltage distortion, and increased system capacity.Limited to 7% Distortion (typical results of 5 – 6% TDD)

HG7 Harmonic Filter Benefits

- High Quality Capacitors:

- Designed, built and tested specifically for use in harmonically rich environments

- Easy Installation:

- Fits easily into motor control centers and ships ready to install

- Uninterrupted Operation:

- The drive continues to operate in the event of an HG7 shut-down

- Flexible Options

- Power Monitor Option

- Component Package Option

Power Quality Issues

Power quality has degraded over time due to the increased use of non-linear loads. The IEEE-519 standard for harmonic distortion was developed to address this problem. An increasing number of utilities are now mandating that this standard be followed.

Harmonics and Power Quality

Variable frequency drives are beneficial for a wide range of applications, however VFDs contain a power conversion process that creates current and voltage distortion which can cause system-wide problems. If non-linear loads represent a significant portion of the entire installed load, this distortion begins to cause problems throughout the electrical system:

- Transformer and distribution equipment overheating

- Random breaker tripping

- Sensitive equipment may fail completely

- Poor power factor

- Reduced system efficiency

The HG7 Passive Harmonic Filter

The HG7 harmonic filter not only limits current distortion to less than 7% (5-6% typical), it also:

- Eliminates nuisance tripping

- Increases drive uptime dramatically

- Improves power factor

- Improves system efficiency & reliability

- Extends equipment life

Meeting IEEE-519 Recommendations on Harmonics

The HG7 harmonic filter provides a cost-effective solution allowing the user to meet IEEE-519 requirements. Using our harmonic analysis software, TCI can help customers meet IEEE-519. Typical applications include:

- Wastewater treatment plants

- Commercial buildings

- Hospitals

- Airports

Performance

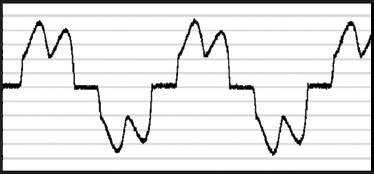

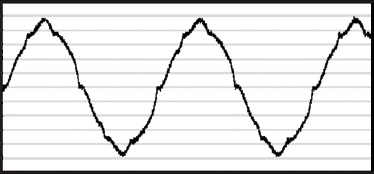

Before HG7

After HG7

Where Drives are a Significant Portion of the Load

The HG7 not only limits current distortion to less than 7% TDD, it also improves true power factor. Multiple package options will allow TCI customers to choose the right filter configuration for the application. Since every power system is different, harmonic mitigation requirements will differ, and even IEEE limits change based on the system loading characteristics. The HG7 product returns the power of choice to the customer, allowing for different configurations to achieve different performance and monitoring results.

Prime candidates for filtering are installations of variable frequency drives or adjustable speed devices in facilities where those drives represent a significant portion of the load, or when specifications call for limited harmonics (like IEEE 519). Filtering would also benefit any application that utilizes sensitive electronic equipment that may be susceptible to harmonic distortion, such as capacitors, control devices, motors, etc. Some industrial examples include printing presses, extruders, machining and pulp and paper. Commercial applications include waste water treatment, pumping and cooling, and HVAC.

HG7 Drive-Applied Harmonic Filters have been proven to be the most effective harmonic distortion mitigation technique available for drives.

Reduce Harmonic Distortion

In a typical industrial facility, where one-half or more of the load may be non-linear loads, resulting distortion may cause sensitive equipment to fail. In commercial/municipal buildings, meeting IEEE-519 is often a critical requirement of power distribution systems.

HG7 Total Demand Distortion (TDD) Guarantee

Properly applied and sized for the application, TCI guarantees that the HG7 will deliver typical results of 5 – 6 % TDD, but no more than 8%, at the filter input terminals. If a properly selected, installed, and loaded HG7 filter fails to meet the guaranteed performance levels, TCI will provide the necessary components or replacement filter at no additional charge. TCI does not take responsibility for additional installation or removal costs, to include, but not limited to, replacement of third party equipment.

Minimum System Requirements

In order to achieve the performance levels as stated in this guarantee, the electrical system must adhere to the following: Line Voltages must be balanced to within ±1%; Voltage at the filter input terminals is 100% (±5%) of filter rating; Source Impedance is at least 3%; Filter loading is 100% (±5%) of filter rating; Load is at least 10% of source rating. TCI cannot guarantee individual results when harmonic distortion exists on the system prior to HG7 installation. TCI does not take responsibility for incorrect installation of the component package option.

IEEE Standard 519-2014

Table 2 – Current distortion limits for systems rated 120 V through 69 kV

| Maximum harmonic current distortion in percent of IL | ||||||

| Individual harmonic order (odd harmonics) a, b | ||||||

| ISC/IL | 3≤h<11 | 11≤h<17 | 17≤h<23 | 23≤h<35 | 35≤h≤50 | TDD |

| <20c | 4.0 | 2.0 | 1.5 | 0.6 | 0.3 | 5.0 |

| 20<50 | 7.0 | 3.5 | 2.5 | 1.0 | 0.5 | 8.0 |

| 50<100 | 10.0 | 4.5 | 4.0 | 1.5 | 0.7 | 12.0 |

| 100<1000 | 12.0 | 5.5 | 5.0 | 2.0 | 1.0 | 15.0 |

| >1000 | 15.0 | 7.0 | 6.0 | 2.5 | 1.4 | 20.0 |

a Even harmonics are limited to 25% of the odd harmonic limits above.

b Current distortions that result in a dc offset, e.g., half-wave converters, are not allowed.

c All power generation equipment is limited to these values of current distortion, regardless of actual ISC/IL.

where

ISC = maximum short-circuit current at PCC

IL = maximum demand load current (fundamental frequency component) at the PCC under normal load operating conditions